Medical devices are essentially high-quality, high-precision and rigorously working industry machines or elements. That is why successful medical device machining is one of the key processes to get your product into the market.

Why A Serious Approach is Important?

Being a medical device manufacturer is surely harsh. You need to take a lot of things into account and your product must be impeccable. Otherwise, you are in deep trouble. The Medicines & Healthcare products Regulatory Agency does not sleep or falter. If the material you’ve chosen hasn’t been tested and approved, or the patients showed at least some small side-effects from using your device, you are done. They have withdrawn over 9000 medical devices from the market last year and they won’t stop. That’s why you should consider every aspect of your product carefully. Today, we are going to review the medical device machining part and why you shouldn’t get into it without prior experience.

Reason 1: Design Errors

Medical device industry is vast. There are a lot of different developers. Some of them are experienced corporations with their own manufacturing plants and a team of designers working in tandem with manufacturing engineers to ensure the optimum configuration of the device from the manufacturing point of view. However, there are smaller companies that are only starting out as well. Those often don’t have the resources to keep manufacturing engineers in their staff. In such cases, designers often forget that their device must be manufacturable. Despite modern CNC medical device machining having the widest technological capabilities among all other manufacturing methods, it still has its limitations that must be checked and avoided. In some cases, the designers make their project manufacturable but at an unimaginably higher price then it could be produced had it been checked by the manufacturing engineers. Naturally, people who are involved in medical prototyping or mass-production know all the possible ways to lower manufacturing costs.

Reason 2: High part wear

Medical devices are withstanding high wear because most of them are operating along with their users, for example, pacemakers work 24/7 as well as implants and suchlike equipment. That’s why it is important to make parts more durable. When we talk about maximizing metal part lifetime, just machining it is not enough. You need to use heat treatment in order to make the part harder, increase its tensile strength and provide the best microstructure for the job that the part will do ( for example, springs are heat- treated differently from gears because they withstand different kinds of loads). The heat treatment is usually set by the manufacturing engineer. If you use the correct treatment, you can make a part perform better despite being made of cheaper material.

Reason 3: Prototyping Costs

In order to bring your medical device into the market, you’ll need to pass a number of tests. Each test will require a prototype, actually, a batch of medical prototypes will be necessary for almost every test. Medical prototyping stages start at proof-of-concept prototypes up to live tests where potential customers get a sample of the final products for free and use them at their leisure while evaluating their efficiency. After each prototyping stage, the design may change a little bit and it may come to a point when you need some specific manufacturing operation but don’t have the equipment for it. That’s why employing prototyping shops is so much better since they have the equipment for every situation.

Reason 4: Specific Materials

Medical devices are known to have very specific requirements in regards to materials. The main materials that require machining both during the medical device prototyping and medical device mass production are metal alloys. Now, you can’t use just any alloys for medical devices. For example, some of the products come in contact with human tissue and they must not poison the body of the customer by chemically reacting with it. Titanium alloys are indispensable in that regard, however, they are very expensive and hard to machine. Steel alloys used for medical device manufacturing process must obviously not rust. That is why stainless steel is used. In addition to that, steel with more carbon percentage is often set for cutting instruments such as scalpels and so on. Both types of steel mentioned above have lower machinability, they have higher tensile strength, higher ductility for stainless steels and higher hardness for instrument steels and require different machining approach. Iron and magnesium alloys are highly promising as materials used for dissolving medical device products such as stints and braces. Such devices are dissolved by blood cells or some other kind of bodily liquid once they’ve performed their function. As you can see, medical device manufacturing processes include a lot of different metal alloys, each of whose is machined differently. And I haven’t even mentioned the different plastic types! Some of them are flexible and need to be frozen prior to machining. As you can see, medical machining is a very variable process and requires the widest range of machining and material competency.

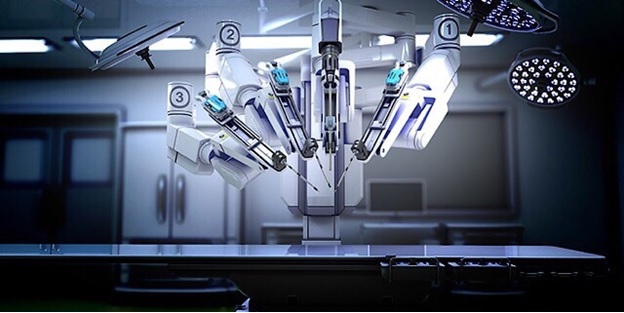

Reason 5: Machining complexity

A lot of modern medical devices are high-precision parts, they have the tolerances bordering on IT5 to work and have the tiniest surface finishes. Almost mirror-like quality. Medical device machining at such close tolerances is torture. Let me tell you a short story that my teacher had once told me. They were manufacturing shafts for vaccine mixing medical machines. The point was that there was some kind of a vaccine that could be synthesized only at a revolution rate of 150000 rpm or more. That required the revolving shaft to be extremely precise and balanced. So, they decided to make a prototype. However, they just couldn’t catch the tolerance while grinding. Something always went amiss. As if the vibration was present. However, the machine shop was ideally quiet, there were just the grinding tool and one machinist working at a time so as not to interfere with other precise jobs. And what do you think? The shop was on the ground floor near a street. And every time, a car passed next to the building, the vibration was enough to send the tool off. They’ve fixed it by loosening the anti-vibration props, on which the machine tool was set so that they became softer and swallowed even the tiniest vibrations.