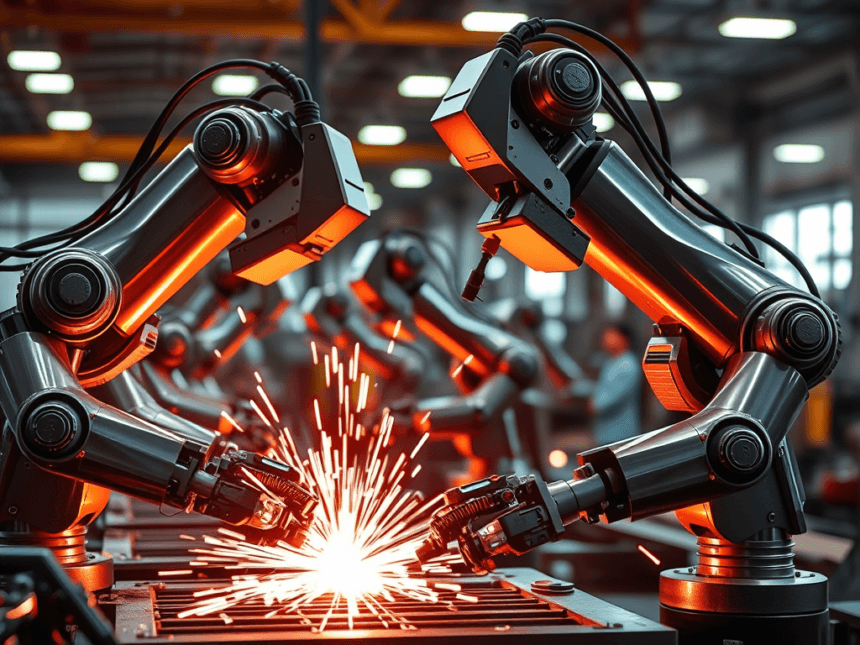

In the competitive landscape of modern manufacturing, efficiency, and quality are paramount. As industries strive to enhance production processes, the integration of advanced technologies has become essential. Among these technologies, collaborative welding robots are making significant strides, redefining how welding operations are conducted. These robots not only improve production efficiency but also enhance product quality and transform workforce dynamics.

The Current State of Welding in Manufacturing

Welding has long been a fundamental process in manufacturing, playing a crucial role in constructing everything from automobiles to large industrial machinery. Traditionally, welding involves skilled laborers performing repetitive tasks that require precision and attention to detail. However, conventional welding practices face numerous challenges, including labor shortages, high rates of human error, and safety concerns.

As demand for high-quality products increases, manufacturers are seeking innovative solutions to address these challenges. The need for improved efficiency, flexibility, and safety in welding has opened the door for collaborative robots, or cobots, to enhance production processes significantly.

Understanding Collaborative Welding Robots

Collaborative welding robots, often referred to as cobots, are designed to work alongside human operators, complementing their skills rather than replacing them. In contrast to conventional industrial robots, which typically work in isolated areas for safety reasons, cobots are designed with advanced sensors and safety features that enable them to operate securely alongside humans.

These robots come with a range of capabilities, including user-friendly programming interfaces, advanced vision systems, and the ability to handle a variety of welding tasks. Popular examples of welding robots in the market include those from companies like Universal Robots and Yaskawa, which are designed specifically for collaborative applications.

Benefits of Collaborative Welding Robots

One of the primary advantages of integrating collaborative welding robots into manufacturing operations is the significant enhancement in efficiency. Cobots can work continuously, alongside human operators, increasing overall throughput. By taking over repetitive and time-consuming tasks, they allow human welders to focus on more complex and value-added activities.

Statistics indicate that manufacturers that have adopted collaborative welding robots have experienced increased cycle times, with some reporting productivity gains of up to 30%. This boost in efficiency not only helps meet production demands but also improves profitability.

Improved Quality and Precision

Welding demands exceptional quality and precision, particularly in sectors like automotive and aerospace, where small defects can lead to serious repercussions. Collaborative welding robots, with their high-precision sensors and advanced programming, ensure consistent quality throughout multiple welding tasks.

By using real-time data and feedback, cobots can minimize defects and ensure that each weld meets strict quality standards. This ability to reduce variability not only improves product quality but also decreases the need for rework, saving both time and resources.

Increased Flexibility and Adaptability

In today’s fast-paced manufacturing environment, flexibility is essential. Collaborative welding robots excel in this area, as they can be quickly programmed to handle different tasks and materials. This adaptability allows manufacturers to switch between production runs without extensive downtime for reconfiguration.

Moreover, cobots can easily integrate new welding techniques and processes, making them suitable for both high-volume production and custom fabrication. This versatility helps manufacturers respond to changing market demands while maintaininghigh levels of efficiency.

Safety Enhancements with Collaborative Robots

Safety is a paramount concern in welding environments, where risks include exposure to hazardous materials and potential injuries from equipment. Collaborative robots play a significant role in enhancing safety by taking on the more dangerous aspects of welding tasks.

Cobots are designed with built-in safety features, such as force-limiting technology and collision detection systems. These features allow cobots to stop immediately if they detect an unexpected obstacle, reducing the risk of injuries to human workers. By alleviating some of the most hazardous tasks from human operators, collaborative welding robots contribute to a safer working environment, ultimately leading to fewer accidents and improved morale.

The Changing Role of Human Workers

The introduction of collaborative robots does not signal the end of human welders; rather, it redefines their roles. Cobotsassist welders by handling repetitive tasks, allowing skilled workers to focus on more complex problem-solving and quality inspections.

As the role of the welder evolves, there is a growing need for upskilling and training. Manufacturers must invest in programs that equip workers with the necessary skills to work effectively alongside robots. This collaborative approach fosters a culture of teamwork, where human expertise and robotic efficiency come together to enhance overall productivity.

Implementation Considerations

When considering the integration of collaborative welding robots into existing workflows, manufacturers must assess several factors. Key considerations include the cost of implementation versus the potential long-term benefits, such as increased productivity and reduced labor costs.

Successful implementation requires careful planning and a clear understanding of how cobots will fit into current processes. It is essential to involve workers in the transition, ensuring they understand the benefits of cobots and how to work with them effectively.

Conclusion

Collaborative welding robots are reshaping the landscape of manufacturing by streamlining production processes, improving quality, and enhancing workplace safety. By embracing the capabilities of welding robots, manufacturers can achieve greater efficiency and adaptability in their operations. As the industry continues to evolve, the collaboration between humans and robots will redefine craftsmanship in welding, paving the way for a more innovative and productive future.